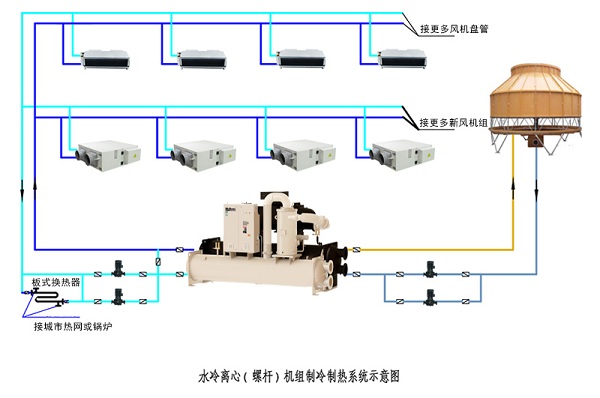

Water-cooled screw chiller is also a type of chiller. Because its main components use screw compressors, the name can be called water-cooled screw chiller. Its frozen effluent temperature ranges from 3 ° C to 20 ° C. It can be widely used in plastics, electroplating, electronics, chemical, pharmaceutical, printing, food processing and other industrial freezing processes where frozen water is used, or in large shopping malls, hotels, etc. Areas where centralized cooling is required for chilled water in various central air-conditioning projects such as factories and hospitals.

What is the difference between a water-cooled screw machine and a centrifuge?

All refer to compressors. The difference is that centrifugal units are more efficient. Mostly chiller. The centrifugal unit is not air-cooled. Air-cooled screws are more common and can be cooled or heated, but the heating effect is not good, so they are mostly used in southern cities. The ordinary screw machine cannot be adjusted steplessly, and the vibration of the screw machine is not small. The installation is not simpler than the centrifuge except for the difference in weight and volume. The pumps, cooling towers, fan coils, and differential pressure bypasses should not be less. . In general, the centrifuge is bigger, the screw machine is smaller, the daily maintenance costs are less, the screw machine is more, the same cooling capacity, the screw machine has more units, and the relative reliability is high. In terms of noise, the screw machine has low frequency noise, and the centrifuge has high frequency noise.