The widespread use of industrial chillers not only drives the refrigeration market, but also allows users to realize the importance of maintenance and daily troubleshooting of industrial chillers.

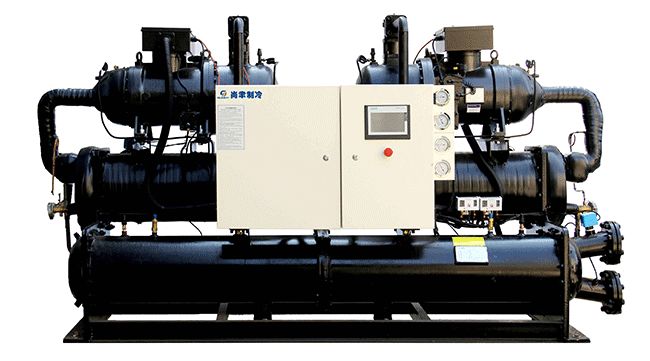

SUNNY-HVAC Water-cooled screw chiller

At present, many users do not know how to troubleshoot routinely after purchasing an industrial chiller. This makes many users of the industrial chiller, in the use of a year or so, there will be a significant deterioration of the cooling effect, resulting in reduced service life, but also improve the operational hazards.

Xiao Bian summed up some common problems, the following is the failure analysis and elimination methods of industrial chillers:

Failure analysis

Cooling water inlet and outlet temperature is abnormal

Condenser inlet water temperature is high (above 32), first of all should check the cooling tower fan is reversed (such as the actual project has such an example); and then through technical demonstration, and in the premise of feasible, adjust the fan blade angle, Increase the air volume of the fan.

Another phenomenon often occurs in the system where multiple cooling towers are used in parallel. When the partial load is running, the water temperature difference between the inlet and outlet of the condenser is too small. It is necessary to check whether each cooling tower has an electric valve, or whether the installed electric valve is installed. Failure caused by cooling water bypass, incomplete cooling.

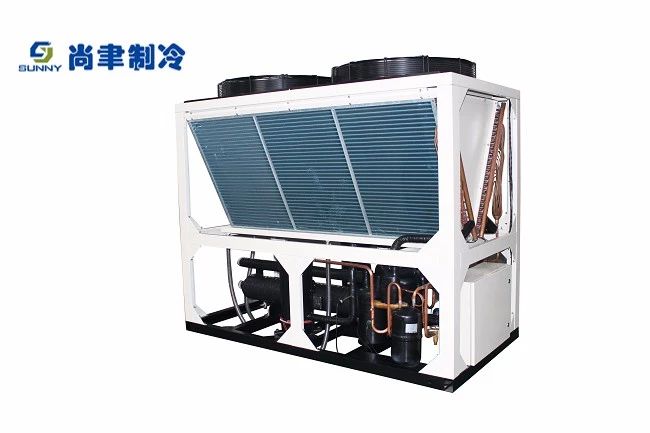

SUNNY-HVAC Air-cooled box chiller

Abnormal pressure difference at inlet and outlet of cooling water

According to the relevant refrigeration theory, the heat release of the condenser directly affects the cooling capacity. Therefore, the cooling water system should be checked first. Based on the pressure loss value on the nameplate of the host computer, if the pressure difference value from the pressure gauge at the entrance and exit is much larger than the normal value, it indicates that there is clogging of the condenser inlet.

Open the inlet end of the water seal head can be seen that the brass diameter is small, because the cooling water is an open system, debris scattered in the catchment tray, with the water flow into the system, once the breakdown of the water filter net will be brought to the condenser inlet So remove debris.

Troubleshooting method

When the fault indicator and protective switch are all normal, the compressor cannot start. Please check:

1. The temperature switch is not adjusted too high or damaged;

2. Switching switch is not damaged;

3. Frost protection switch is not damaged;

4. Is the pressure switch tripped or damaged?

5. Is the compressor overload protector damaged or tripped?

6. The electromagnetic relay coil is not damaged and the overload protector is not damaged;

7. Is the tank level too low?

8. Please check whether the chilled water flow switch has been damaged;

Note: If the above control switch or circuit is faulty, the compressor cannot operate.

SUNNY-HVAC Air-cooled modular chiller

The above methods are frequently used in daily operations. With these methods, we can help us to use industrial chillers in a better, safer, and more convenient manner. At the same time, the service life of industrial chillers is also prolonged, and the replacement is reduced. Cost, improve work efficiency.

For more information, please follow SUNNY-HVAC!